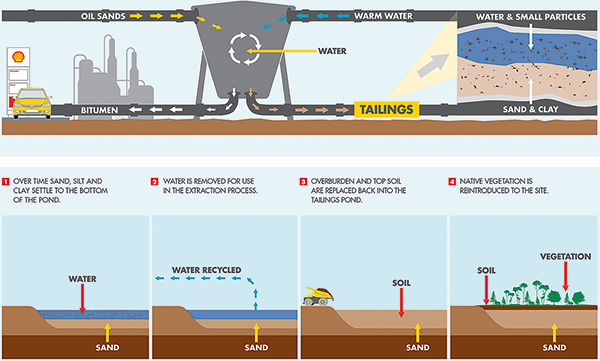

The oil sands mining process separates bitumen from the sand which generates tailings. Tailings include a mixture of water, sand, clay and residual hydrocarbons, as well as naturally occurring traces of heavy metals and chemicals. Tailings are stored in tailings ponds which allow for the sand to settle at the bottom and the water to be recycled. (See diagram below, step 1).

Our tailings are managed carefully to prevent contamination of local water courses, and to minimise risk to wildlife and the surrounding environment. Dried tailings will be used to restore the landscape once mining has finished. (See diagram below, step 3). Tailings ponds at the Muskeg River and Jackpine mines covered 37 km2 at the end of 2014, compared with 24 km2 the previous year. This increase is in line with the planned development of the mine. The land space of tailings ponds has increased to both support the ongoing processing of oil sands and allow reclamation to start on existing ponds.

Alberta has regulations to reduce the amount of liquid tailings and we work with the government to meet these requirements. Shell has invested more than C$400 million during the past decade to develop technologies that speed up the drying process for tailings. We successfully piloted a tailings centrifuge to accelerate the drying process using technology shared through COSIA. The centrifuge works more than twice as fast as our previous process. We will operate four centrifuge units at AOSP in 2015 and expect that each centrifuge unit will process about 1 million cubic metres of tailings each year. This will reduce the land space needed for storing tailings.

View the content of the diagram above as accessible version.