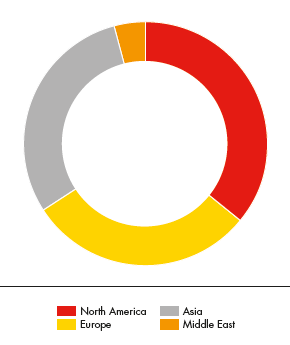

Shell base chemicals 2013 capacity %

We have more than 80 years of experience in the chemicals industry, and produce and sell petrochemicals to more than 1,000 industrial customers worldwide. Our range of petrochemicals includes base chemicals, such as ethylene, propylene and aromatics; and first-line derivatives, such as styrene monomer, propylene oxide, solvents, detergent alcohols, and ethylene oxide. Our customers, many of them leading companies in their own fields, use these products to make everyday items, such as plastics, detergents, textiles, medical equipment and computers. In total, we sold more than 17 million tonnes of bulk petrochemicals in 2013.

Over many decades we have developed the proprietary technologies, processes and catalysts that enable Shell to compete strongly in our core petrochemical markets. For example, our OMEGA technology converts ethylene to ethylene oxide, which is used to make a wide range of industrial and consumer products, including polyester films and fibres, engine coolants and antifreeze. It is considered the most efficient technology of its kind, using about 20% less steam and producing about 30% less waste water than equivalent traditional thermal conversion mono-ethylene glycol (MEG) technology. It also produces significantly less carbon dioxide per tonne of MEG than conventional processes.

In Singapore, we are building a demonstration unit to manufacture the chemical ingredient diphenyl carbonate, a versatile engineering plastic used in a wide and growing variety of applications, from optical media equipment, household items and automotive components, to electronics, sheeting and films.

We will continue to focus on the synergies among our petrochemical plants, refineries and Upstream business to increase the supply of the best available feedstock for our facilities.

Our Chemicals strategy is based on selective growth at existing sites through capacity increases, efficiency and integration improvements, and strengthening our feedstock sources. Securing integrated growth projects with partners and developing technologies to convert gas to chemicals are also critical strategy components.

In Asia, we have taken the final investment decision to debottleneck our Singapore ethylene cracker on Pulau Bukom (Bukom Island). This is expected to increase the capacity of olefins and aromatics produced there by more than 20%. We have also announced plans for additional capacity at our Jurong Island petrochemicals facilities. These investments are expected to add 140,000 tonnes per annum (tpa) of high-purity ethylene oxide (HPEO) capacity, 140,000 tpa of ethoxylation capacity and more than 100,000 tpa of polyols capacity.

In the Middle East, we are working with our joint venture partner, Saudi Basic Industries Corporation (SABIC), to progress plans for the expansion of various projects at the Saudi Petrochemical Company (Sadaf). We are also looking to expand our partnership beyond Saudi Arabia.

Shell and Qatar Petroleum have awarded the front-end engineering and design contract for a proposed world-scale petrochemicals project (Shell interest 20%) in Ras Laffan Industrial City. The scope includes a capacity of 1.5 mtpa of mono-ethylene glycol and 0.3 mtpa of linear alpha olefins.

We are also developing plans to build a potential world-scale ethylene cracker with integrated derivative units in the Appalachian region of north-east USA. Our chemicals manufacturing site at Geismar, Louisiana, is already one of the largest integrated ethylene oxide (EO) and ethoxylation facilities in the world. We are considering plans to debottleneck the existing assets, plus invest in a new crude EO unit.

In Europe, we are also considering a debottleneck project in the crude ethylene oxide plant and investment in a new HPEO purification column at our Moerdijk site in the Netherlands.