The ability to produce large quantities of natural gas trapped tightly in rock pores has revolutionised the energy picture in North America in recent years. Producing tight gas requires a technique called hydraulic fracturing, or fracking, to release the gas from the rock. This approach has been used over many decades, but new drilling techniques have recently enabled greater volumes of gas to be produced from a single drilling site, reducing our operational footprint.

The environmental impacts of producing tight and shale gas have caused concerns among some communities. These concerns include air emissions, the use of large amounts of water, contamination of local water supplies and the disposal of waste generated by production. Questions have also been raised over the possibility of methane escaping into the air during production, and tight gas development causing minor earth tremors.

In 2011, we published a set of global onshore operating principles to address concerns around the development of onshore tight gas, specifically relating to hydraulic fracturing. They also cover our approach to producing oil trapped in similar rock formations. These principles are based on our focus on safety, continuous improvement, collaboration with regulators, and engagement with local residents in which we are transparent about how we operate and the impacts of our activities (see Onshore oil and gas operating principles).

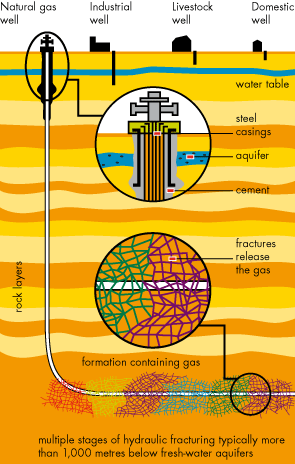

Hydraulic fracturing uses large quantities of water, which is injected at high pressure into a reservoir to break open the rock deep underground and free the gas. The injection of water mixed with small amounts of chemicals has led to concerns that fracking might affect local water supplies or contaminate fresh-water aquifers below ground. Shell has long favoured public disclosure of fracturing fluid contents. We disclose all chemicals used in fracking to the extent allowed by our suppliers, and we support legislation requiring the release of this information.

We are currently producing tight gas in North America and China, and we are exploring for additional resources in other countries. In Australia, the joint venture Arrow Energy (Shell interest 50%) is producing gas from coal seams to convert to liquefied natural gas.

Our approach puts safety and the protection of the environment at the forefront of our operations. The tight gas reservoirs we access are typically more than 1,000 metres below fresh-water aquifers. Our wells are lined with multiple layers of steel casing and are cemented from the surface to far below the water table (see diagram above).

We reduce our need for fresh water by recycling used water. At Groundbirch in western Canada, for example, we have invested around C$10 million to build a waste-water treatment facility with the Dawson Creek city authorities. The plant, due to start operating in 2012, will reclaim 4,000 cubic metres of waste water each day and will supply our operations with all the water it will need. In the north-east USA, we recycle almost all of the water produced with gas during drilling at the Marcellus shale gas project, significantly reducing our fresh-water needs.

We have reduced our use of fresh water by around 50% at our Pinedale tight gas project in Wyoming, USA, by recycling water produced with the gas. The state’s Department of Environmental Quality also recognised Shell in 2011 for the steps we take to prevent contamination from storm water running off our drill sites. These include raised banks around the drill sites and additional vegetation to control erosion. Catalytic converters fitted to our Pinedale drilling rig engines reduce emissions by up to 90%.

Activities at drill sites and the impact of truck traffic can raise concerns among local people. At Pinedale and at our Haynesville operations in Louisiana, USA (see box below), we are disturbing the land as little as possible by drilling multiple wells from single sites. At our Marcellus operations in Pennsylvania, USA, we have plans to transport water by rail, reducing the need for trucks.

OPINION

“Shell has exhibited in Pennsylvania a genuine commitment to shale development practices that exceed regulatory requirements in several areas, and meet higher standards to protect the environment and help develop local economies. Shell hires local people and reduces water usage through recycling the waste water from drilling activities. It does not discharge used water into Pennsylvanias streams and rivers. Most impressively, Shell adopted in 2011 strong environmental and community standards for shale development. The company has shown a willingness and openness in engaging with stakeholders, including non-governmental organisations, to find ways to develop shale gas responsibly in Pennsylvania.”

John HangarSpecial Counsel, Eckert and Seamans Law Firm, and

former Secretary of the Pennsylvania Department of Environmental Protection,

Pittsburgh, Pennsylvania, USA

HAYNESVILLE: BEING A GOOD NEIGHBOUR

In north-west Louisiana, USA, Shell has been preparing to increase the production of gas tightly trapped in shale rock. The Haynesville field is a gas formation deep beneath the area’s pine forests and red dirt farmland. Nearby, there is a small town of the same name. In 2006, the first discoveries of natural gas improved job prospects for people living there.

Almost everyone we employ at Haynesville is from the local area. We also support many local organisations that focus on education and developing job skills. We provided funds for the creation of the Center for Integrated Engineering Technologies at a local college and actively support other job programmes at schools in the area.

Along with opportunities, concerns exist over truck traffic, noise, land disturbance and water use. We work closely with the community to listen, learn and address these concerns. Since 2007, we have drilled around 200 wells in the area as we explored for gas. In 2012, we expect to increase production of tight gas. New techniques allow the drilling of many wells from a single location, reducing our footprint. Temporary pipelines delivering water to our sites have already reduced truck traffic. We also reuse water wherever possible. Excess water produced with the gas is transported for disposal in line with regulations.