Personal safety

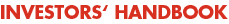

Fatal accident rate (FAR)

fatalities per 100 million working hours

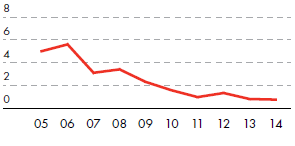

Total recordable case frequency (TRCF)

injuries per million working hours

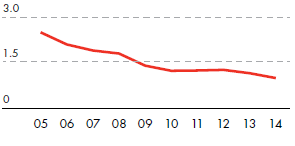

Lost time injury frequency (LTIF)

injuries per million working hours

In 2014, following steady and significant improvements in our safety performance in recent years, we achieved our lowest ever number of injuries per million working hours – the total recordable case frequency (TRCF). We also achieved our lowest ever level of injuries that led to time off work in 2014, measured as lost time injury frequency (LTIF).

Sadly, five people lost their lives while working for Shell in 2014, three of which happened during operations and two as a result of transport accidents. Our fatal accident rate (FAR) – the number of fatalities per 100 million hours worked – improved in 2014 compared with 2013 and we achieved the lowest FAR that Shell has recorded.

Tragically, one colleague was on board the Malaysia Airlines flight, MH370, which has been missing since March 2014. We also lost four colleagues and eight of their family members in the Malaysia Airlines disaster over Ukraine in July 2014.

Process safety

Since 2011, we have introduced reporting of process safety in line with industry standards. In 2014, we achieved our best ever performance for both Tier 1 (57 in 2014; 65 in 2013) and Tier 2 (194 in 2014; 246 in 2013) operational process safety events. For Nigeria, process safety events related to sabotage and theft are recorded separately (91 Tier 1 and 48 Tier 2 events in 2014). To help improve performance in this area we investigate and learn from incidents, small and large.

External opinion

“As far back as the mid-1980s, senior leaders at Shell recognised the need to manage the personal, technical and organisational factors involved in safety incidents to reduce human error. At Leiden University in the Netherlands, we have worked with Shell to develop, test and help implement new ways of improving safety.

It has proved challenging to move from a technical approach to safety to one that is more focused on personal and organisational factors. However Shell is now recognised as a global leader in safety and is a role model for other organisations. The next step for Shell to achieve zero accidents is to focus more on preventing repeat accidents by actively implementing the recommendations drawn from the lessons learned and by sharing these lessons.”

Jop Groeneweg

Assistant Professor, Unit of Cognitive Psychology, Leiden University, the Netherlands

We design our facilities to reduce the likelihood of incidents, but also to reduce the impact should something unexpected happen. For example, in 2014 we had a number of larger incidents where the impact of the event was reduced by the design of the facility. These events were:

- a fire in a toluene tank in the Rhineland refinery (Germany);

- an explosion in a processing unit in the Moerdijk chemicals facility (the Netherlands);

- a boiler explosion at the Sarnia refinery (Canada);

- broken equipment at an onshore gas well in Permian (USA) leading to a gas leak; and

- a leak at a flow station facility in Nembe (Nigeria) largely contained on-site.

Safety in the community

The Groningen gas field, 40% owned by the Dutch government, is the largest onshore gas resource in Europe. Since operations began in 1963, it has been a major contributor to the energy system in the Netherlands. It is operated by the “Nederlandse Aardolie Maatschappij B.V.” (NAM, Shell interest 50%). In recent years, induced earthquakes occurring in the field have caused concerns particularly among local residents.

A series of studies are being conducted by independent organisations in close cooperation with the Netherlands’ Ministry of Economic Affairs, the Meteorological Institute and the State Supervision of the Mines, as well as several science institutions around the world to better understand this unprecedented situation.

The Netherlands’ Ministry of Economic Affairs has lowered the maximum gas production. It has also initiated a financial package to address damage claims; preventively reinforce houses and support a social performance programme for the area. Concerns of local communities are being addressed by a dedicated NAM team and claims for damage are being processed by the “Centrum Veilig Wonen” (Safe Living Centre), which operates independently.