Carbon capture and storage

Carbon capture and storage – or CCS – is the name given to a combination of technologies that captures and stores carbon dioxide (CO2) deep underground, preventing its release into the atmosphere.

At Shell, we believe the world will need CCS to achieve the ambition of net-zero emissions. CCS is already being used around the world to capture CO2 from power generation and industrial processes with around 25 million tonnes of CO2 captured and stored globally each year. Many companies have further CCS projects in development. There is considerable potential for the future deployment of CCS in a variety of industrial sectors including power, iron and steel.

Quest, Canada

In Alberta, Canada, Shell operates a joint venture (Shell interest 60%) to develop the first commercial-scale CCS for reserves extracted from our oil sands operations. The facility is designed to capture up to 35% of the current CO2 emissions from the Scotford Upgrader – the site where bitumen is processed into synthetic crude oil. The captured CO2 is stored in a porous rock layer about 60 km away and more than 2 km below ground.

Quest started operating in 2015. At full capacity it can capture and store more than 1 million tonnes of CO2 each year – equivalent to the emissions from about 250,000 cars. Since its start-up, Quest has reduced CO2 emissions by 315 kilotonnes. The provincial government of Alberta and federal government of Canada have provided C$865 million to support the development of Quest.

Shell and our joint-venture partners are freely sharing any data or intellectual property generated by the Quest project to help others advance CCS projects and demonstrate its value on an industrial scale.

Monitoring Quest

Quest is designed to meet all the requirements for the safe and permanent storage of CO2. We have developed a rigorous monitoring programme to ensure that the CO2 remains safely and securely underground. This includes continuous pipeline monitoring and early-warning systems, groundwater sampling and 3D seismic surveying. Throughout the development of Quest, we conducted an extensive consultation programme with nearby communities. We share our baseline results from our monitoring programme with the local community.

Shell Cansolv

CCS technology developed by Shell Cansolv is used at the Boundary Dam power station in Saskatchewan, Canada. It is Saskpower’s largest coal-fired power station and a significant source of power for the region. Both sulphur dioxide and CO2 are captured from the power station.

Peterhead, UK

At the Peterhead power station in Scotland, which is operated by the British energy company SSE, we were, until recently, designing a full-scale gas CCS project for a natural gas-fired power plant. The CCS technology was being designed to capture and move CO2 from the power station offshore through pipelines for storage deep under the seabed of the North Sea. Unfortunately, the UK government withdrew potential funding in late 2015, and the project did not proceed. We learnt much about how to reduce the costs of future CCS projects. The technical data and reports from our work is made publicly available.

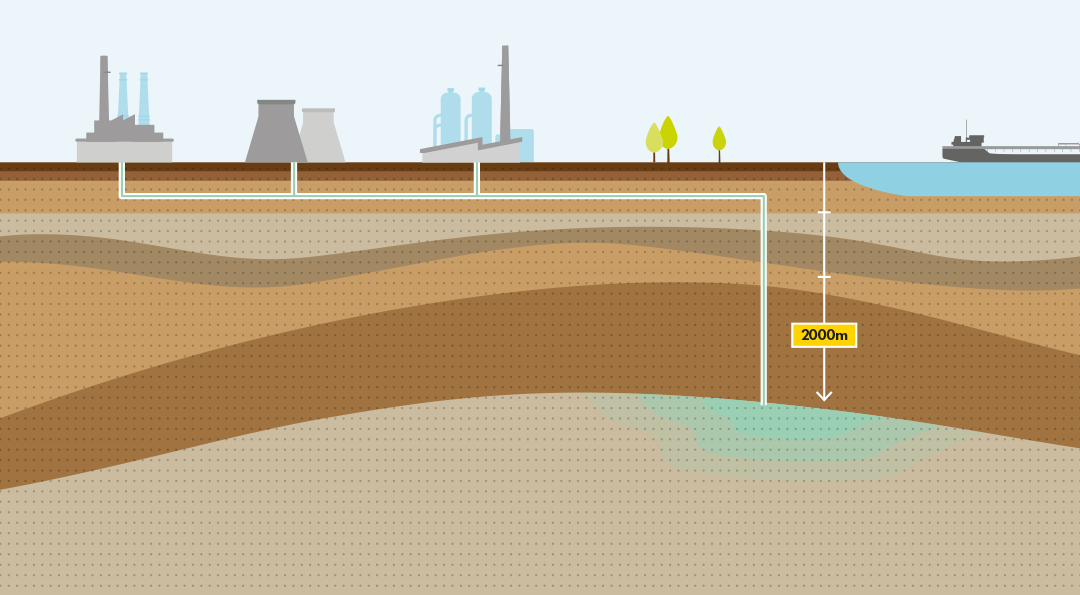

Carbon Capture AND STORAGE Overview

Capture

CO2 capture separates CO2 from gas, before it is emitted, using a chemical solvent. The captured CO2 is separated from the solvent and compressed into a liquid form for transport.

Transport

CO2 is generally pumped along a pipeline, taking the CO2 from the industrial site where it has been produced, to its storage site which may be onshore or offshore.

Storage

CO2 is injected deep underground into the microscopic spaces in porous rocks. A layer of impermeable rock, called a cap rock, lies directly above the porous rocks ensuring that the CO2 remains there permanently.