Flaring

The flaring of natural gas produced with oil wastes valuable resources and contributes to climate change. At Shell, we are working hard to minimise flaring associated with oil and gas production.

When oil is extracted from a reservoir, gas is produced as the oil is brought to the surface. Operational flaring is sometimes carried out for safety reasons. However, continuous flaring occurs when there are no facilities to capture the gas – this wastes valuable energy resources and releases carbon dioxide into the atmosphere.

Shell’s policy is to reduce any continuous flaring or venting at our operations to a level as low as technically and financially feasible. We also aim to minimise operational flaring required for safety reasons such as during the start-up of a new facility. Our flaring policy is set out in our health, safety, security, environment and social performance (HSSE & SP) Control Framework, including the requirement that new facilities are designed so as not to continuously flare or vent.

Shell has been an active member of the World Bank sponsored Global Gas Flaring Reduction (GGFR) partnership since 2002. This public-private partnership promotes and facilitates progress in reducing flaring by working collaboratively to find alternative uses for gas that would otherwise be flared. As part of the GGFR partnership, the World Bank has developed a Zero Routine Flaring by 2030 initiative to encourage governments, companies and development organisations to work closely together to end continuous flaring. Shell joined the initiative in April 2015 before it was launched. The initiative aims to identify ways to use associated gas from projects at the design stage – for example, to generate electricity for local communities.

Our performance

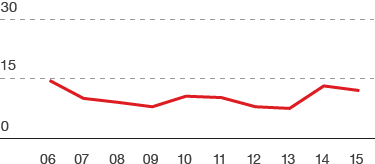

Flaring – Upstream

million tonnes CO2 equivalent

In 2015, we reduced flaring from facilities we operate from the level reported in 2014 despite an increase in flaring levels in Malaysia in line with increased oil production in 2015. More than 90% of our flaring occurs in Iraq, Nigeria, Malaysia and Qatar.

In Iraq, flaring decreased slightly in 2015 as Shell Iraq Petroleum Development (Shell interest 45%) safely delivered the first phase of a gas-capturing system at our Majnoon facilities. When the second phase is complete, the project will capture about 65% of the gas that would otherwise be flared. The start-up of this project marks a significant milestone in our efforts to reduce gas flaring at Majnoon and deliver natural gas for power generation for the people of Iraq.

The flaring volume from Shell Petroleum Development Company’s (SPDC) joint-venture facilities in Nigeria was reduced by 85% between 2002 and 2015. The flaring intensity (the amount of gas flared for every tonne of oil and gas produced) was reduced by around 70% over the same period. Flaring from SPDC facilities decreased in 2015, due to divestments and improved operations at our assets. Progress was also made on several gas-gathering projects, which are now at advanced stages of completion. For example, we have installed a gas-gathering plant at the Oloma Station that is ready for final commissioning. However, the planned start-up dates for two other major gas gathering projects have been delayed due to a lack of adequate joint-venture funding from our government partner.

Flaring increased in Malaysia, due to increased oil production at Gumusut Kakap (Shell interest 33%) which started production in 2014. The associated gas was flared until reinjection equipment was ready for use in October 2015. The gas is now injected back into the hydrocarbon reservoir from which it came.

At our Pearl gas-to-liquids (GTL) plant in Qatar, flaring takes place for operational reasons. In 2015, our flaring decreased due to lower activity while maintenance and enhancements to the plant took place. This helped lower operational flaring by using more waste gas for electricity generation.

We expect our overall flaring levels to continue to decline in 2016 as the gas-gathering facilities in Iraq and Malaysia become operational.

Wider flare reduction efforts

Basrah Gas Company (BGC, Shell interest 44%) is a joint venture with South Gas Company and Mitsubishi. It captures associated gas that would otherwise be flared from three non-operated oil fields in southern Iraq (Rumaila, West Qurna 1 and Zubair) for use in the domestic market. BGC recently achieved a record production of 515 million standard cubic feet of gas each day. If used for power generation, this would be enough to power more than 3.5 million homes. In 2015, BGC in Iraq and SPDC in Nigeria received awards from the World Bank Group for their flare reduction work. (See external opinion).

Bjørn Håmsø

Programme Manager, Global Gas Flaring Reduction Partnership,

World Bank, Washington D.C., USA

External opinion

“Gas flaring at oil production sites around the globe has been steadily declining for several years. However, progress has been too slow, particularly when the world is demanding strong climate action and when many oil producing countries have severe energy shortages. If the amount of gas flared globally was instead used for power generation, it could produce more electricity than the whole of Africa currently consumes.

In 2015, the World Bank introduced a new initiative – Zero Routine Flaring by 2030 – to accelerate efforts to reduce global gas flaring. Shell demonstrated leadership by endorsing the initiative before its official launch in Washington, D.C. Its endorsement was an impetus for other oil companies to join. We expect Shell to continue its progressive, proactive role to turn the initiative into action.

The Zero Routine Flaring by 2030 initiative means new oil fields will be developed with solutions that avoid flaring or venting. Existing legacy flaring must end as soon as possible and no later than 2030. In late 2015, Shell received a Global Gas Flaring Reduction Partnership Excellence Award for its achievements in Iraq and Nigeria. We look forward to continuing our partnership towards a more sustainable energy future.”