Flaring

The flaring of natural gas wastes valuable resources and contributes to climate change. We are working hard to reduce flaring associated with oil and gas production.

When oil is extracted from a reservoir, gas is also produced as the oil is brought to the surface. This is known as associated gas. This gas can be captured and used alongside the oil. When there are no facilities to gather the gas, or they have insufficient capacity, it is sometimes flared, or burned. Flaring is also carried out for safety reasons to relieve pressure in the production system. Flaring wastes valuable energy resources and releases greenhouse gas into the atmosphere.

Shell’s policy is to reduce any routine flaring or venting of associated gas at our operations to a level as low as technically and financially feasible. We also aim to minimise operational flaring required for safety reasons such as during the start-up of a new facility. Our flaring policy is set out in our Health, Safety, Security, Environment and Social Performance (HSSE&SP) Control Framework. It includes the requirement for all facilities to be designed to export, use or reinject associated gas that is produced, and all facilities have to meet strict performance criteria.

Shell has been an active member of the World Bank-sponsored "Global Gas Flaring Reduction" (GGFR) partnership since 2002. This public-private partnership helps reduce flaring by working collaboratively to find alternative uses for gas that would otherwise be flared. As part of the partnership, the World Bank has developed the "Zero Routine Flaring by 2030" initiative, which Shell signed up to in 2015. This encourages governments, companies and development organisations to work together to end the disposal of gas by flaring. The initiative aims to identify ways to use gas from oil production – for example, to generate electricity for local communities.

Our performance

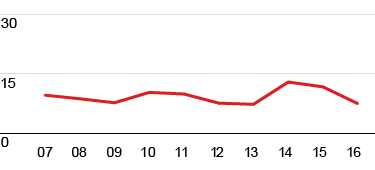

Flaring – Upstream

million tonnes CO2 equivalent

Enlarge image

More than 70% of flaring from Shell-operated fields in 2016 occurred in Iraq, Nigeria, Malaysia and Qatar. New facilities brought online in Malaysia and Iraq have helped reduce our flaring from 11.8 million tonnes of carbon (CO2) equivalent in 2015 to 7.6 million tonnes in 2016, including the additional fields added to our portfolio from the acquisition of BG in 2016. Work continues to bring additional gas gathering facilities online in Iraq and Nigeria to reach our goal of no routine flaring by 2030, while continuous improvement efforts will reduce operational flaring.

In Iraq, Shell Iraq Petroleum Development (Shell interest 45%) safely delivered the second phase of a gas-capturing system at our Majnoon facilities. The system captured about 65% of the gas that would otherwise be flared in 2016, which was around 90 million standard cubic feet per day. The delivery of this phase marks a significant milestone in our efforts to reduce gas flaring at Majnoon and deliver natural gas for power generation in Iraq.

Basrah Gas Company (BGC, Shell interest 44%) is a joint venture with Iraq’s South Gas Company and Japan’s Mitsubishi. It captures gas that would otherwise be flared from three non-Shell-operated oil fields in southern Iraq (Rumaila, West Qurna 1 and Zubair) for use in the domestic market. In 2016, BGC processed an average of 574 million standard cubic feet of gas each day from these fields. This is equivalent to the amount of energy needed to power more than 4.5 million homes.

These projects are helping to improve the electrical infrastructure of the country and deliver much-needed energy to the population. They required collaboration with the Iraqi government, joint-venture partners, domestic companies and non-governmental organisations.

In Nigeria, flaring from Shell Petroleum Development Company’s (SPDC) joint-venture facilities fell by more than 90% between 2002 and 2016. Flaring from SPDC facilities decreased further in 2016, mainly due to production outages as well as to operational improvements. Progress was also made on several gas-gathering projects. However, the planned start-up dates for two major gas-gathering projects continue to be delayed by security issues and a lack of adequate joint-venture funding from our government partner.

In Malaysia, the associated gas flaring reported in 2015 at the Gumusut (Shell interest 29%) and Kikeh fields has been eliminated by the introduction of a fully operational system in 2016 that injects gas back into the hydrocarbon reservoir. This will maximise production from the oil field.

In Qatar, at our Pearl gas-to-liquids plant (Shell interest 100%), flaring takes place for operational reasons. In 2016, further enhancements to the plant took place, to reuse more waste gas. (See Natural gas).

At Shell, we continue to develop solutions that eliminate flaring while, where possible, bringing gas to markets for domestic and international use.