Preparing for emergencies

We work to ensure we have the necessary resources to deal with spills, leaks, fires and explosions, both offshore and onshore. We regularly test our response procedures and capability so we can respond rapidly to an incident. We recognise the need for urgent and transparent communication with relevant stakeholders, such as local authorities, in response to an incident.

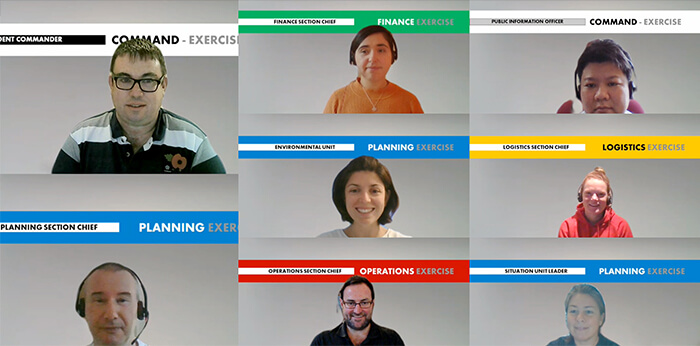

In 2020, COVID-19 restrictions made it difficult to run large-scale training in person. As a result, we accelerated our drive towards virtual support and new ways of working to maintain our response readiness by, for example, using online collaboration tools.

Shell employees and contractors connected virtually in 2020 as COVID-19 restrictions made it difficult to run oil spill exercises in person.

We trained around 500 employees and contractors on a large-scale virtual oil spill exercise and several smaller exercises. These involved businesses in Brazil, Canada, Qatar, Singapore, Trinidad and Tobago, the UK and the USA and included oil spill scenarios related to our shipping, offshore production, and refining operations. Exercises involved our emergency response contractors, joint-venture partners, and regulatory authorities to test our organisational capability to manage a worst-case spill incident.

In the UK, we carried out a two-day simulation of an oil spill from an offshore drilling operation that required the use of specialised equipment from local suppliers and from Italy, Norway, and Singapore. The exercise involved around 200 people and tested procedures to contain the release, such as deploying floating barriers and applying dispersant to the oil, and required working with freight contractors and customs authorities.

We have worked with maritime authorities and emergency response partners in Scotland, UK, to train local fishermen in oil spill response methods, such as oil sampling and dispersant effectiveness.

You can watch the training exercise that took place in March 2020 at www.youtube.com/watch?v=v3RKllZPcyg

We also used our incident management system to help co-ordinate the evacuation of platforms due to COVID-19 and hurricanes in the US Gulf of Mexico, and to help around 2,000 seafarers stranded on vessels to get home during the pandemic.

Spills

Shell has procedures to prevent operational spills. We also have routine programmes to maintain facilities and pipelines, to improve reliability and to reduce spills.

But spills still occur for reasons such as operational failure, accidents or sabotage. We investigate and learn from spills to improve our performance and aim to clean up the areas around operations that are affected by spills, irrespective of the cause.

Spills performance

Spills – operational [A]

[A] All spill volumes and numbers are for hydrocarbon spills of more than 100 kilograms. We have updated some of our historical figures following a review of the data.

The volume of operational spills of oil and oil products in 2020 was 0.4 thousand tonnes, an increase from 0.2 thousand tonnes in 2019. This was partly due to an underground leak of around 0.3 thousand tonnes (plus or minus 30%) of light gas oil at the Rheinland refinery in Germany, formed at some point between 2016 and 2019, with the volume established in 2020. We have agreed to a remediation plan with local authorities, which is currently being implemented, and are publishing progress reports on the refinery’s webpage.

There were 69 operational spills of more than 100 kilograms in 2020 compared with 67 in 2019. We have programmes in place to reduce the number of operational spills over the long term.

Spills – sabotage [A] [B]

[A] Sabotage- and theft-related spills of more than 100 kilograms. We have updated some of our historical figures following a review of the data.

[B] All sabotage- and theft-related spills occurred in Nigeria except in 2016 (0.001 thousand tonnes).

The number of spills caused by sabotage and theft decreased to 122 in 2020 from 156 in 2019. The volume of these spills decreased to 1.4 thousand tonnes in 2020 from 2.3 thousand tonnes in 2019. Sabotage and oil theft remained a significant cause of spills in the Niger Delta, Nigeria.

Visit www.shell.com/process-safety for more on our emergency response procedures.