GTL

Shell’s gas-to-liquids (GTL) capabilities unlock value from natural gas by converting it into valuable, high quality liquid hydrocarbon products, ranging from transportation fuels and motor oils to ingredients for everyday necessities like plastics, detergents and cosmetics. This offers natural gas resource holders access to the global oil products market, which is attractive for those who want to diversify risk.

Liquids processing unit at our Pearl GTL plant, one of the key components to maximising natural gas usage.

Shell’s GTL technology is founded on more than four decades of research, development and commercial experience. Our proprietary Shell GTL technology is at the heart of our GTL plants. We have invested more than $1 billion and filed over 3,500 patents in developing our gas-to-liquids process. In 1993, we opened the world’s first commercial GTL plant in Bintulu, Malaysia with a capacity of 14,700 barrels of oil equivalent per day (boe/d). In 2011, we started up Pearl GTL in Qatar with a capacity of about 140,000 boe per day of high-quality liquid hydrocarbon products and 120,000 boe per day of natural gas liquids (NGL) and ethane. In 2015, we successfully completed the first major turnaround of Pearl train 1. In 2016, we successfully completed a major turnaround of the second train.

Recognising the market demand for smaller GTL facilities between the size of SMDS (Bintulu) and Pearl GTL, Shell has developed a more flexible technology that can be used for GTL plants in a range of sizes.

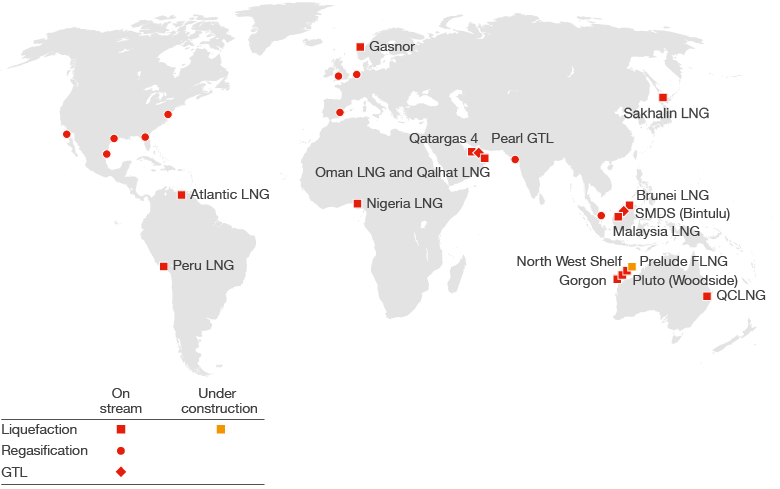

Integrated Gas assets: LNG liquefaction plants, LNG regasification terminals and GTL plants