In Focus: Queensland Gas Company

Key dates

2015

- Queensland Curtis LNG (QCLNG) liquefaction plant begins commercial operations

- Pipeline sale completed

2014

- First LNG produced from the QCLNG liquefaction plant on Curtis Island

2012

- Binding agreements signed for the sale of certain interests in the QCLNG project for $1.93 billion

2011

- Contract signed with Tokyo Gas for sale of 1.2 mtpa of LNG

2010

- QCLNG project sanctioned

- Contract signed with CNOOC for sale of 3.6 mtpa of LNG

Our Queensland operations, which Shell acquired through the BG acquisition, feature around 30 gas processing facilities, three water treatment plants and a two-train LNG export facility on Curtis Island. Queensland Curtis LNG (QCLNG) has 8.5 mtpa of capacity and will continue to generate revenue for at least two decades. QGC assets comprise:

- Licences in four onshore areas of producing and potential gas supply covering a total of around 28,000 square kilometres.

- Major shareholdings in the two-train liquefaction facility on Curtis Island, including 100% equity in common facilities such as the LNG storage tanks and jetty.

- The 140-megawatt Condamine power station near Miles, which supplies the national electricity market.

Exploration and production

As at end December 2015, the first phase of upstream development had seen more than 2,650 wells drilled across a 3,800 square kilometre area. The natural gas produced from the Surat Basin is about 98% methane and, therefore, requires minimal processing.

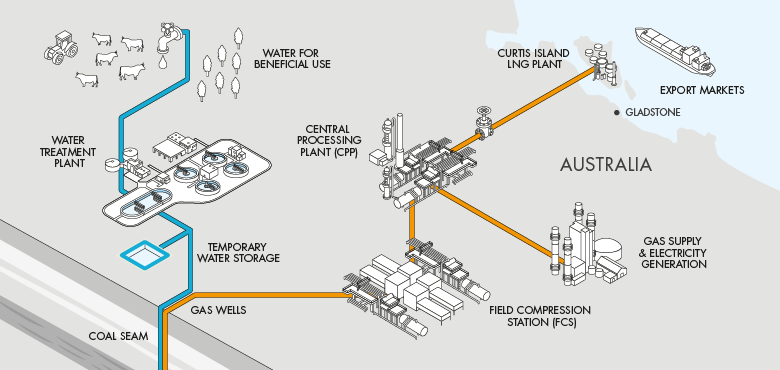

Gas and water are separated at the well site and the gas is transferred through underground gathering pipelines to field compression stations (FCS) which remove water and impurities and increase the pressure of the gas, improving the flow rate through a steel pipeline to a central processing plant (CPP). Several FCSs are linked to each CPP. At the CPP the last traces of water are removed and the gas is further compressed for transportation in high-pressure pipelines to domestic gas infrastructure or to the liquefaction plant on Curtis Island.

Given the dewatering and ramp up profile of coal seam gas, we are utilising both equity gas and third-party gas to ensure the LNG plant operates at capacity. During the ramp up of the LNG plant, third-party gas has provided less than 20% of throughput, as expected, and will be less than 5% at plateau.

Infrastructure

Water is produced when wells are brought into production. The reduction in pressure of the water in coal seams releases the natural gas from the seams. QGC has developed two major water treatment plants for the purpose of treating the water which is then available for the beneficial use, such as for irrigation or urban use. QGC aims to make up 97% of all water processed through the plants available for these purposes.

Liquefaction

The two-train, 8.5 mtpa capacity liquefaction plant has been developed to produce LNG from natural gas sourced from coal seams. The QCLNG plant is sited on a 270-hectare site on Curtis Island, near Gladstone, on the Queensland coast and comprises Train 1 (50% interest) and Train 2 (97.5% interest) each of 4.25 mtpa capacity, as well as the associated facilities (100% interest) such as the two 140,000 cubic metre capacity storage tanks.

Natural gas supply

Meeting domestic gas supply commitments under long-term contracts with domestic customers is the first priority for production. These contracts are with power stations, industrial users and gas retailers with the longest extending to 2032. Between 2016 and 2027, QGC will continue to supply the Queensland market under long-term contracts. Gross gas production to supply QCLNG, as well as the domestic market, is expected to total 1.4 bcf/d at plateau.

LNG Shipping & Marketing

As a key portfolio supply source, QCLNG volumes will be delivered to our worldwide customers, primarily those in Asia including China, Japan and Singapore.

Schematic of QCLNG project